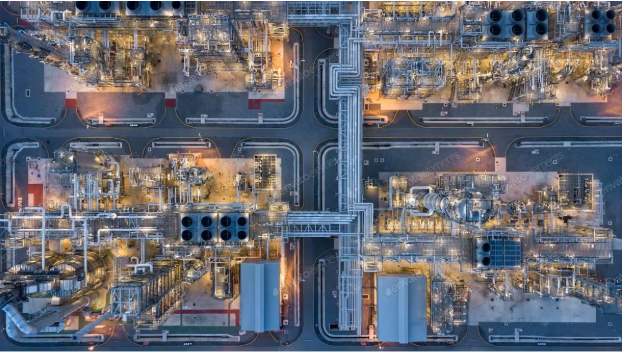

Maintenance & Turnaround Services:

Plant turnaround management is all about strategically shutting down a facility, typically a process plant, for extensive maintenance and improvement activities. It’s a meticulously planned and executed event crucial for keeping industrial plants running smoothly and efficiently.

SME can support managing Turnaround preforming the below phases.

1. Strategic Planning: This initial phase sets the overall goals, defines the scope of work, and estimates budget and resources needed.

2. Detailed Planning & Scheduling: Here, a detailed breakdown of tasks, timelines, and resource allocation is created. Permits, material procurement, and contractor coordination happen in this phase.

3. Pre-Turnaround Activities: This involves tasks like equipment isolation, depressurization, and preparation for safe maintenance work.

4. Turnaround Execution: This is the core phase where the planned maintenance, inspections, and upgrades are carried out. Safety and quality control are paramount here.

5. Post-Turnaround Activities: Plant systems are brought back online, equipment is performance-tested, and handover to operations occurs.

- Benefits of Effective Turnaround Management:

- Increased plant reliability and efficiency

- Improved product quality and yield

- Enhanced safety for personnel and the environment

- Reduced maintenance costs in the long run

- Extended equipment lifespan